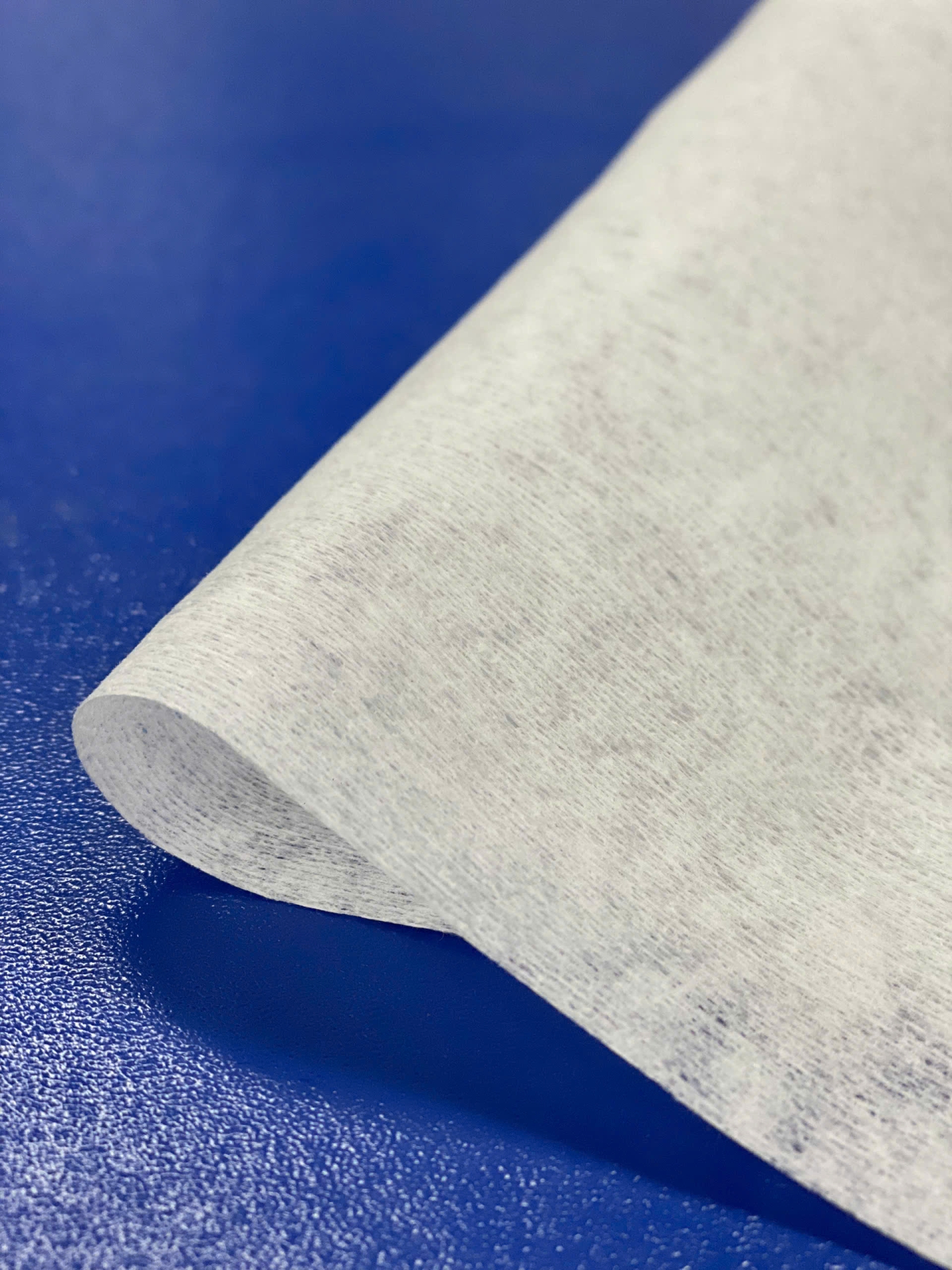

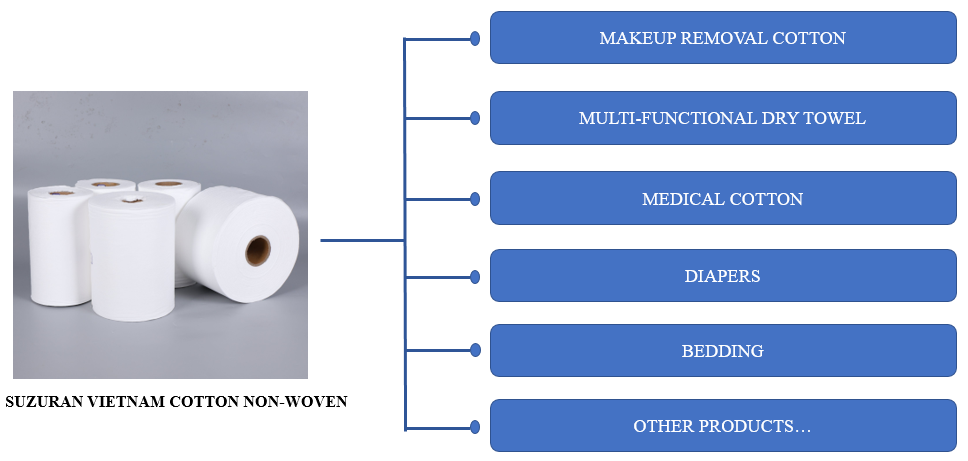

Suzuran's "Post-bleaching" Process

Suzuran applies the “Post-bleaching” method in the production of cotton nonwovens. This method streamlines the process by applying bleaching after the water jet forming stage, instead of before. Traditionally, cotton undergoes bleaching and drying after harvesting, followed by a water jet process to bond the fibers, requiring two drying stages. In contrast, the Post-bleaching method allows bleaching of the formed cotton rolls directly, reducing the drying process to one stage. This change significantly cuts energy consumption and CO2 emissions, contributing to environmental sustainability.

In addition, this method minimizes the risk of bacterial contamination associated with pre-bleached cotton, enhancing product hygiene before packaging. Overall, the Post-bleaching technique is a more efficient and environmentally friendly approach to cotton nonwovens production

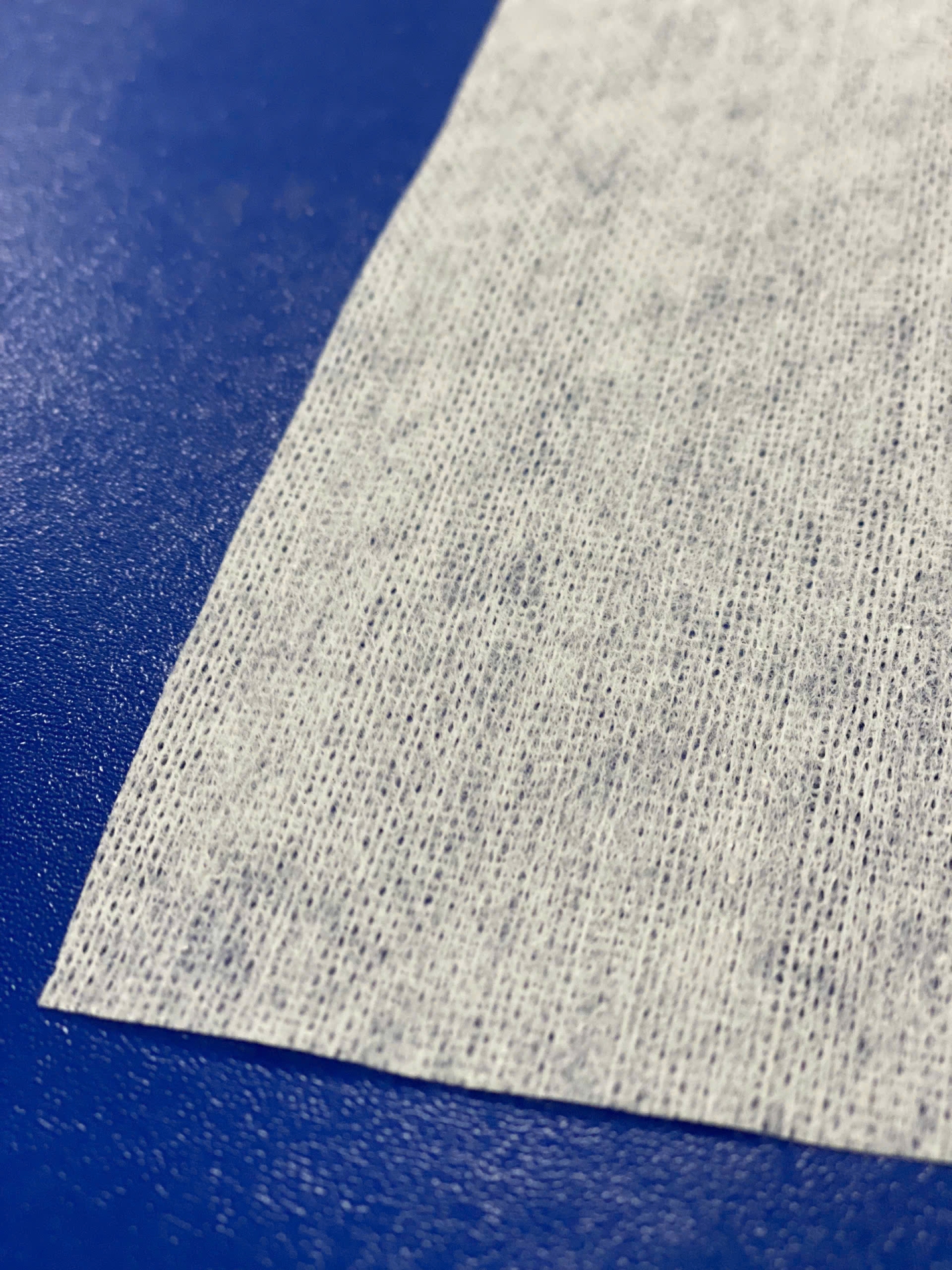

Advantages of the “Post-bleaching” method

- Product meets medical standards.

- Reducing CO2 emissions, lowering pollution levels and minimize bacterial contamination.

- Can mix raw materials from different countries according to the intended use.

- Capable of high-speed, large-volume production, meeting most production requirements.

- Achieve high whiteness thanks to the use of modern bleaching technology.